Trigger spring

Torsion spring

Stress spring

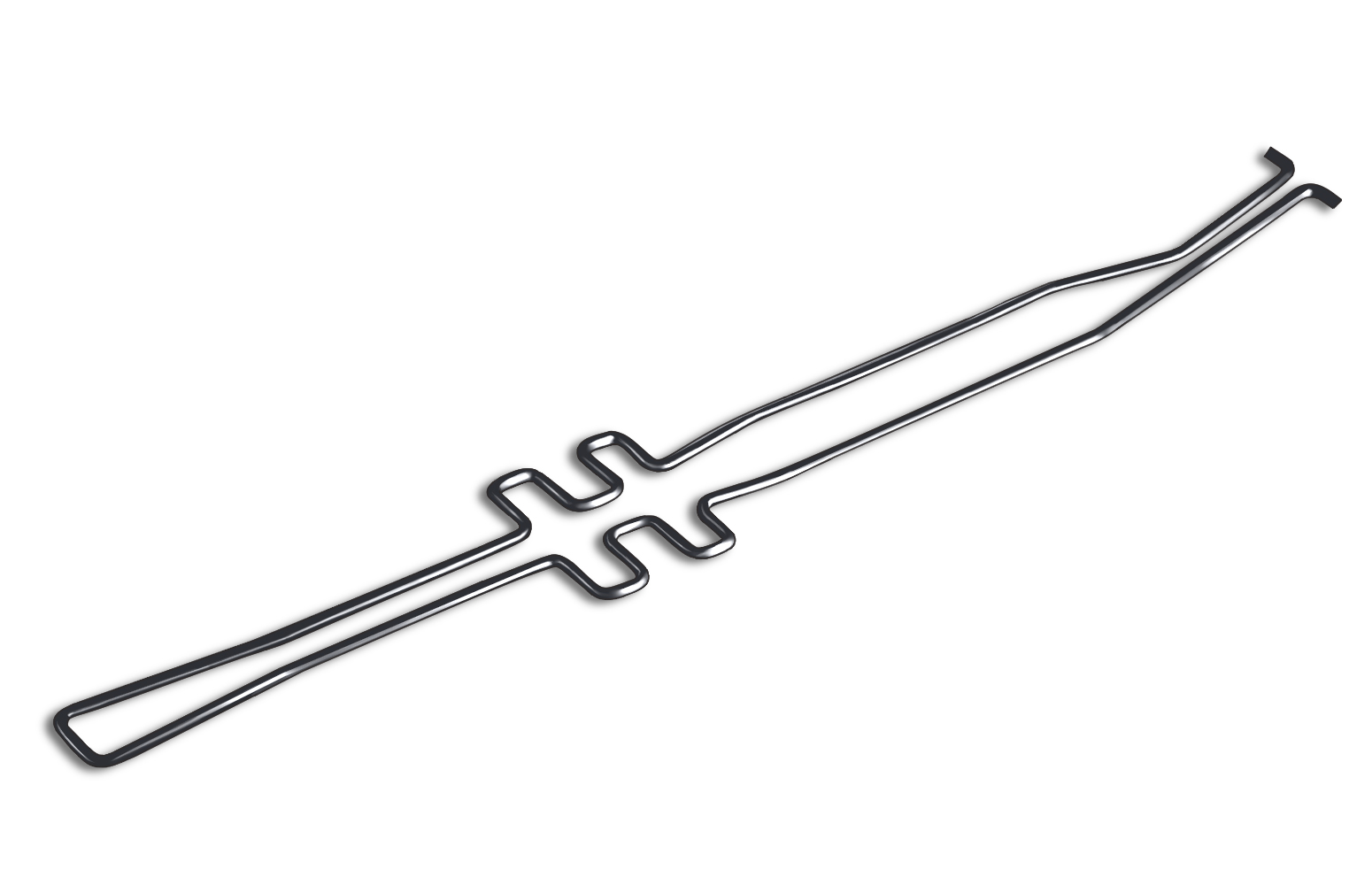

Odd-shaped springs

Double torsion spring

We accept orders from design consultation and prototyping of Precision wire spring products.

- I want to make a part using Precision wire spring products.

- We do not know the optimum material or shape for our product specifications.

- I have lost my original drawings.